Our high production capacity and reliable inspection system enable a stable supply of high-quality products.

Our Product Manufacturing Division has a total of 42 presses, including 21 high-speed presses. This extensive equipment enables us to meet all our customers’ demands. By carrying out thorough quality control based on our press management technologies accumulated since our foundation, we have also established a system in which “high quality is our standard quality.

Press management technologies developed since our foundation

We supply high-level products with the management technologies accumulated over the years, having built our own original production control system, maintenance system, and quality control system.

With our production control system, we continually strive to eliminate waste by maintaining inventory and prices at appropriate levels.

To ensure traceability, our shipment control enables us to track which batch of products has been sent to which destination and as part of which order (delivery time).

High production capacity with high-speed presses

At our company, we have 21 high-speed presses alone, ranging from 25t to 100t, enabling production that varies between 100 shots per minute with thick material and 500 shots per minute with thin material. This high production capacity thanks to our extensive equipment enables us to meet the diverse needs of our customers.

Various ways of increasing production efficiency

We have addressed cost reduction by seeking various ways of improving the productivity of each process.

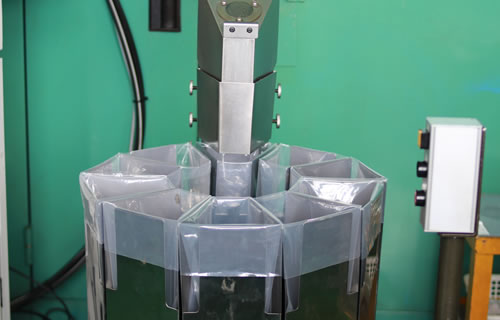

[Example : Automatic switching (bottom)]

In the process of winding the product onto the shipping reel and packaging it, we have increased the operating rate by installing a machine that counts up and switches automatically.

Efforts to reduce work

At our company, we have introduced specialized machinery for incidental tasks such as lifting heavy loads, with the aim of eliminating accidents and reducing workload. Installing such specialized machinery has also had the effect of increasing work efficiency.

(The photo shows a machine that sucks up scraps formed in the product shaping process and discharges them in the correct place)

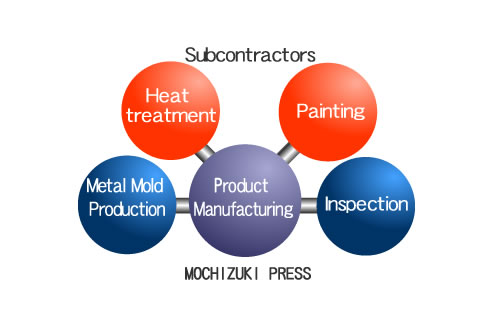

Network of reliable subcontractors

We ask reliable subcontractors to carry out the various heat treatment and plating processes, and have established a system that lets us contract out all processes right up until product completion.

Complete inspection equipment and reliable inspection system

We guarantee quality by carrying out first-piece inspections of products to be manufactured followed by interim sampling inspections and final product inspections for each lot. A traceability system has also been constructed so that inspection results can be tracked later.

Our inspection equipment is gathered in an inspection room, where we have established an efficient system for testing products.

Providing quality assurance through 100% inspections

We have installed a 100% inspection system using cameras and camera images to measure the dimensions and check the appearance of products coming from the presses.

If the purpose of use of a product requires a very high level of precision in each item, we guarantee quality by carrying out a 100% inspection.

Eco-friendly washing system

We have installed environmentally-friendly fully automated washers that use hydrocarbons instead of substances that cause climate change such as trichloroethylene and CFCs.